An Electrician Invented a Better Panel Filler. Here’s How He Did It

If you’ve spent any time working inside a panel, you already know how fast a simple job can turn into a scramble. Loose fillers drop, the panel’s live, other trades are crowding in, and suddenly you’re wishing the gear in front of you was built a little smarter. That’s exactly the situation that pushed Chris Busto to design the BusGuard Panel Filler. In this interview we did at NECA, he walks us through why he created it, what the invention process was really like, and the lessons he thinks every electrician should keep in mind.

Meet Chris, the Electrician Behind BusGuard

Chris: My name is Chris. I’m an electrical contractor. I do commercial, residential, and industrial. I’ve been in the trade since 2011, and I’ve got my own company, CVB Electric. I’m also the inventor of the BusGuard Panel Filler.

Chris: My name is Chris. I’m an electrical contractor. I do commercial, residential, and industrial. I’ve been in the trade since 2011, and I’ve got my own company, CVB Electric. I’m also the inventor of the BusGuard Panel Filler.

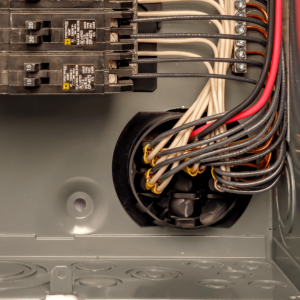

This panel filler, instead of going on the front cover, goes onto the bus bar like a circuit breaker, so when you take your panel cover off, your panel fillers aren’t going to be falling to the floor or sliding out of place. They stay fixed to the bus bar, protecting you from all the electric shocks or arc flashes.

Last year, we had the original version for Siemens, Eden, and Homeline. This year, we came equipped with the new QO Panel Filler, which goes into Square D QOs. They can be used both in single-phase and three-phase panels, if they happen to be a combination panel.

Rack-A-Tiers: What kind of work do you mainly do right now?

Chris: I was doing a lot of residential, new houses, renovation stuff, but I’ve kind of changed to commercial, which I kind of enjoy a little bit more.

Rack-A-Tiers: What do you enjoy more about commercial electrical work?

Chris: Money. I make more money doing commercial, and it’s kind of easier, actually. You’re not dealing with homeowners as much. You’re dealing with big businesses that just want the job done. So, whatever needs to be done, they’ll pay for it. Also, using a lot of armored cable and EMT piping is just fun. Plus, it’s mostly surface-mount stuff, so you don’t have to go into attics or anything.

Check out the BusGuard Panel Filler

Why Invent the BusGuard Electrical Panelboard Filler?

Rack-A-Tiers: What made you decide to invent the BusGuard and put in the work it takes to introduce a new product to the electrical industry?

Rack-A-Tiers: What made you decide to invent the BusGuard and put in the work it takes to introduce a new product to the electrical industry?

Chris: I was working on a panel one time, and when I took off the panel cover, all the panel fillers just fell right onto the ground. I’m working in the dark with a headlamp on, and now I’ve got to try to find all these panel fillers and try to put them back on the panel.

Meanwhile, I’ve got to get to another job, so it’s just wasting time, right? So that was one thing. Then another time, I was working in a panel in a new house. A lot of other trades are in the house. Painters, the cabinet guys, all need plugs, and I’m trying to work on the panel. Usually, I like to turn it off and not work live, but in that case, I had to work live. A couple of times, I had actually touched the bus bar and shocked myself, and the ground wire touched the bus bar and did a short circuit. So, I was like, why are we, as electricians, putting our hands inside panels and having the risk of shocking ourselves?

I put those things together, and I came up with the BusGuard. It fits right under the bus bar like a circuit breaker, and you will not be taking this thing out until you replace it with a circuit breaker. It’s always going to be there to protect it.

Developing an Electrical Tool Prototype

Rack-A-Tiers: How did the prototyping process go? A lot of people get stuck there when they have new tool ideas.

Rack-A-Tiers: How did the prototyping process go? A lot of people get stuck there when they have new tool ideas.

Chris: It’s been pretty good. I had some good help along the way. My manufacturer has been really good to me. They help me with my drawings and everything. The whole certification process takes a bit of time and money though, lots of money. Eventually, we got there, and it was good overall.

Rack-A-Tiers: Were there any big hurdles or problems that came up while working on the BusGuard?

Chris: Probably all these big panel manufacturers. We’re making a product that goes into someone else’s panel, so there are a lot of things to keep in mind. Other than that, it’s been pretty smooth. I’ve had nothing but good feedback, which is nice.

Advice for New Electricians

Rack-A-Tiers: Do you have any advice for the newer electricians out there who are just starting out?

Rack-A-Tiers: Do you have any advice for the newer electricians out there who are just starting out?

Chris: Safety is the biggest thing. Make sure you’re always keeping yourself safe. Do what you can to keep yourself out of harm’s way. At the end of the day, we want to go home to our family.

Be creative. Think of stuff for yourself, too. You’re on the tools every day. There’s always something that might make your life easier. Don’t be shy to try to take that risk and actually try to make something for yourself.

Rack-A-Tiers: What three qualities do you think make a good electrician?

Chris: You’ve got to have a good attitude. You’ve got to want to work. You’ve got to be patient, especially if you own the company like myself. Things aren’t always going to go right throughout the day, whether you forgot something at the wholesaler or the customer wants something else done that you didn’t plan for. You’ve just got to be patient. You’ve got to be calm. It’s not worth stressing out. At the end of the day, it’s just work. Get the job done and go home.

Rack-A-Tiers: How about those electricians who think you should always do every job in the hardest, least-efficient way possible so that everyone sees that you don’t have “soft hands”? What are your thoughts on that attitude?

Chris: I think these tools are made to make your life easier. The more tools you have, the easier it makes your life. Work smart, not hard. If you have the right tools, your job is going to go a lot more smoothly.

Chris’ Favorite Electrical Tools

Rack-A-Tiers: Speaking of which, what are some of your favorite tools in your bag right now?

Rack-A-Tiers: Speaking of which, what are some of your favorite tools in your bag right now?

Chris: I do like the Rack-A-Tiers Croc’s Strippers. They really fit your hand well. They strip the wire well. I just like using them. It feels right.

I also like the Pulse Tracer. You just plug it into a socket, then go to the panel, and it tells you what breaker it is. You can save some time instead of running back and forth a hundred times.

And I like my Greenlee wire cutters with the ratcheting for when you’re doing big service upgrades or anything where we’re cutting like 250 kcmil cables. That’s not easy.

And there’s a new product called the Wire Waffle that I’ll be using lots of. That’s a great product.

Get the Wire Waffle NM Cable Connector

The Future of the Electrical Industry

Rack-A-Tiers: What are your thoughts on the future of the electrical industry? As a tool inventor, is there anything that you’re excited by? Anything you’re worried about?

Rack-A-Tiers: What are your thoughts on the future of the electrical industry? As a tool inventor, is there anything that you’re excited by? Anything you’re worried about?

Chris: I’m glad that AI is not going to be changing our industry too much or taking jobs away from electricians, because you always need electricians.

I’m curious to see how the lighting and smart controls change. I’m curious to see how much easier it’s going to be in the future with Google Home or Apple Home. You always see movies that show the future, and you’re just talking to your house and telling it what you want done. I’m kind of curious to see if that actually happens.

I’m also excited for the different tools that will come along. Rack-A-Tiers has a lot of tools. A lot of people come by our booth, and they actually really enjoy the new gear. I’d be curious to see if there’s anyone else who comes up with their own ideas and tries to make the work a little bit easier.

Closing Thoughts for Future Inventors

Talking with Chris shows how much real-world experience shapes the best ideas in the trade. The BusGuard came from everyday frustrations, safety concerns, and the willingness to actually do something about them. If you’re already sketching your own invention, his advice is simple: stay safe, stay curious, and look for ways to make the work better. The electrical industry always needs people who are willing to step up and build the tools that move it forward.

Check out the BusGuard